Introduction

The energy industry is undergoing a radical change in the world. A more distributed, complex, and intelligent paradigm is emerging to challenge the traditional, centralized model of energy generation and distribution due to the demands of decarbonization, technological innovation, and changing economic drivers. At the heart of this new terrain is a basic knowledge of two different approaches to energy projects: Behind-the-Meter (BTM) and Front-of-the-Meter (FTM). This difference is no longer a specialized technicality of utility engineers; it is a strategic framework that energy professionals in the solar, storage, and electric vehicle charging sectors need to consider when making investment decisions, business models, and infrastructure development.

This article gives a conclusive discussion of the two approaches, which is aimed at giving you the clarity you require to understand which of the two approaches is aligned to your strategic goals.

What is Behind the Meter

A Behind-the-Meter (BTM) energy system refers to any power generation, storage, or management asset located on the customer’s side of the utility’s electrical meter. The defining characteristic of a BTM system is its primary purpose: to generate its own energy to serve the on-site energy demand of a specific home, commercial building, or industrial facility.

These systems operate in parallel with the main utility grid but are designed first and foremost to reduce the amount of electricity the customer needs to purchase from the utility. This “self-consumption” model is the foundational principle of BTM. The common types include rooftop solar PV arrays, battery storage systems (BESS) installed in a factory, and electric vehicle (EV) charging stations at an office building. While these systems are typically interconnected with the grid, allowing for the export of excess energy or import of power when on-site generation is insufficient, their main function is to directly serve the local load, thereby providing a measure of energy independence and cost control to the end-user.

What is Front of the Meter

A Behind-the-Meter (BTM) energy system is any power generation, storage, or management asset on the customer side of the utility electricity meter. The main feature of a BTM system is its main objective: to support the local energy demand of a particular home, commercial building or industrial facility.

These systems are run in parallel with the main utility grid but are primarily intended to minimize the quantity of electricity that the customer must buy off the utility. The principle of BTM is this so-called self-consumption model. Typical applications are rooftop solar PV systems, battery energy storage systems (BESS) at a factory, and electric vehicle (EV) charging at an office building. Although these systems are normally connected to the grid, so that excess power can be exported or power imported when on-site generation is inadequate, their primary purpose is to directly supply the local load, thus giving the end-user some degree of energy independence and cost control.

Behind the meter vs in front of the meter: Key Differences

Although both BTM and FTM systems are essential parts of the contemporary energy system, they are fundamentally different in their essential features. These differences are critical to comprehend by any stakeholder, whether a contractor, integrator, or operator, to recognize the opportunities in the market and design suitable energy solutions.

| Dimension | BTM | FTM |

| Scale & Location | Small, on-site systems (kW–MW) at customer premises | Large, centralized plants (MW–GW) on utility side |

| Ownership | Customer or third-party | Utility, IPP, or investor |

| Goal | Cut energy costs, boost resilience | Sell power for profit |

| Economic Model | Avoid retail rates, reduce peaks | PPAs or wholesale market sales |

| Grid Role | Reduce local demand, may export surplus | Feed and stabilize the grid |

| Control | Owner-controlled | Grid operator-controlled |

Scale & Location

The most obvious distinction is the physical size and place.

By their nature, BTM systems are smaller and geographically dispersed. They can be as small as a few kilowatts (kW) of a residential rooftop solar system to several megawatts (MW) of a co-generation plant at a large industrial facility. They are placed wherever the end-user they serve is located, on rooftops, in parking lots, or in the mechanical room of a building.

FTM projects, on the other hand, are characterized by their huge size. They are utility-scale, usually tens or hundreds of megawatts, and even gigawatt (GW) capacity. This needs huge areas of land, frequently in remote areas with abundant energy resources like high solar irradiance or steady wind patterns, and far away from the final consumers.

Ownership

The ownership models are radically different.

The energy consumer, a homeowner, a commercial entity such as a retail chain, or an industrial manufacturer, is usually the owner of BTM assets. Alternatively they can be owned by a third-party developer who sells the power directly to the on-site customer under a private PPA.

Conversely, FTM assets are held by large, specialized owners, including regulated utility companies, Independent Power Producers (IPPs) or large infrastructure investment funds. These owners do not deal in on-site energy management, but wholesale power generation.

Primary Goal

The strategic objective of both approaches is essentially different.

The main objective of a BTM project is economic savings and operational resilience of the owner. It is an investment in cutting a significant operating cost (electricity) and hedging against the risk of grid outages.

An FTM project is aimed at direct revenue. It is an asset that is constructed to generate a commodity-electricity and sell it at a profit in the wholesale market.

Economic Model

Such divergent objectives result in different economic models.

The BTM model creates value through cost avoidance, namely, the high bundled cost of retail electricity supplied by the utility, which comprises generation, transmission, distribution, and a variety of taxes and fees, ultimately impacting consumer energy bills. It is a cost-reduction measure.

The FTM economic model is wholesale based. It depends on its ability to obtain long-term PPAs that will ensure a fixed price of its electricity over 15-25 years or winning bids in competitive energy markets.

Grid Interaction

Another area of contrast is interaction with the grid.

BTM systems are created to reduce the burden on the local distribution system. When they generate more power than the site uses, this excess can frequently be sold back to the electric grid with financial compensation policies such as net metering.Their main effect, however, is to decrease grid demand.

The grid is FTM systems. They are the main sources of energy supply and their production is actively controlled and despatched by grid operators (such as an ISO or RTO) to ensure the constant, delicate balance between system-wide supply and demand.

Control & Independence

Lastly, there is a difference in the locus of control.

A BTM system owner has greater control over the system, determining when to charge or discharge a battery or how to prioritize energy flows. This gives a high degree of energy self-sufficiency.

The financial owner of an FTM asset retains the financial title, but transfers most of the operational control to the grid operator. The plant has to be responsive to dispatch signals and operate within the tight technical parameters needed to serve the national grid, leaving it with minimal operational autonomy.

Applications of Behind the Meter vs Front of the Meter Projects

The strategic decision on Behind-the-Meter (BTM) and Front-of-the-Meter (FTM) projects is based on the objectives of on-site energy optimization or mass supply to the grid.

Applications of Behind the Meter

BTM solutions are placed on the property of a consumer to control energy expenses directly, enhance reliability, and meet sustainability goals. The most important applications are:

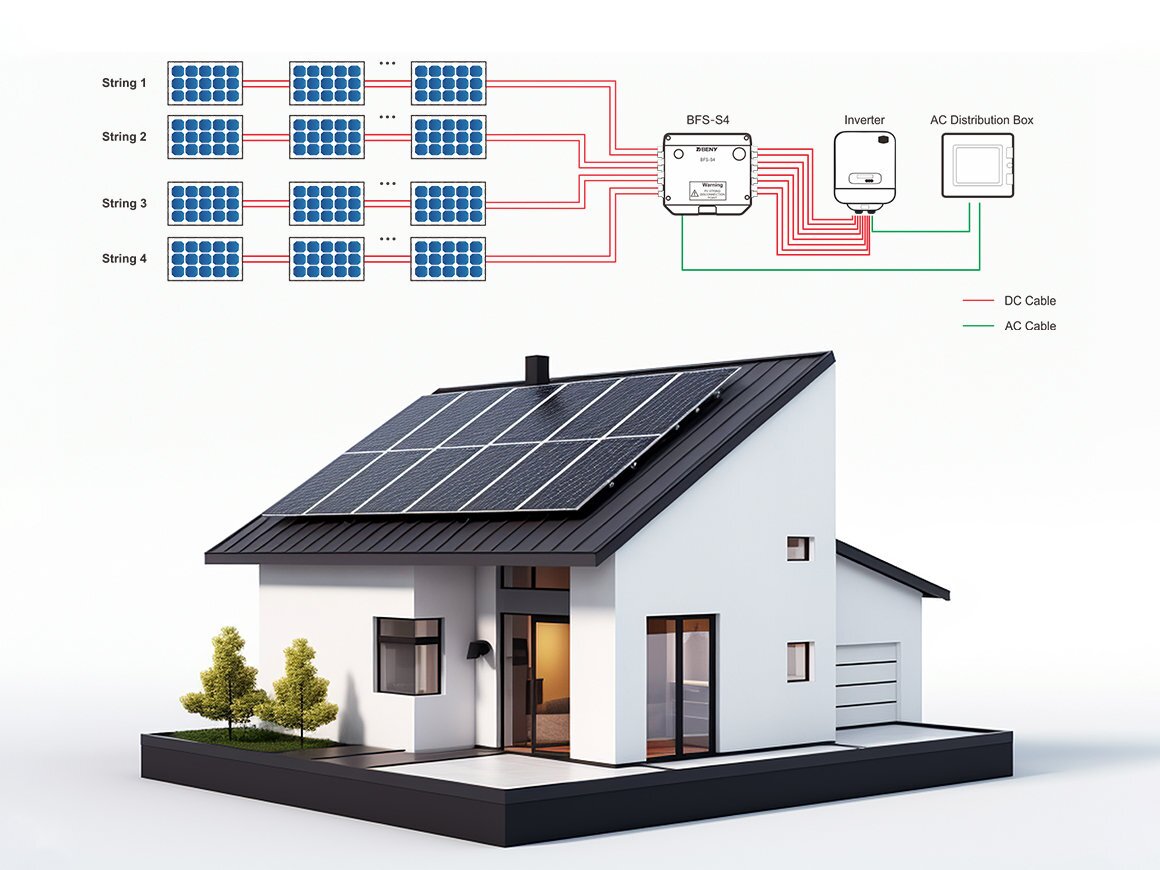

- Solar PV Systems: Installed on rooftops or other available land to produce clean electricity to be used on-site, which directly decreases the quantity of power bought off the utility.

- Battery Energy Storage Systems (BESS): Combined with solar to store surplus energy. These systems are used to discharge during high cost peak hours (peak shaving) and to supply backup power during outages.

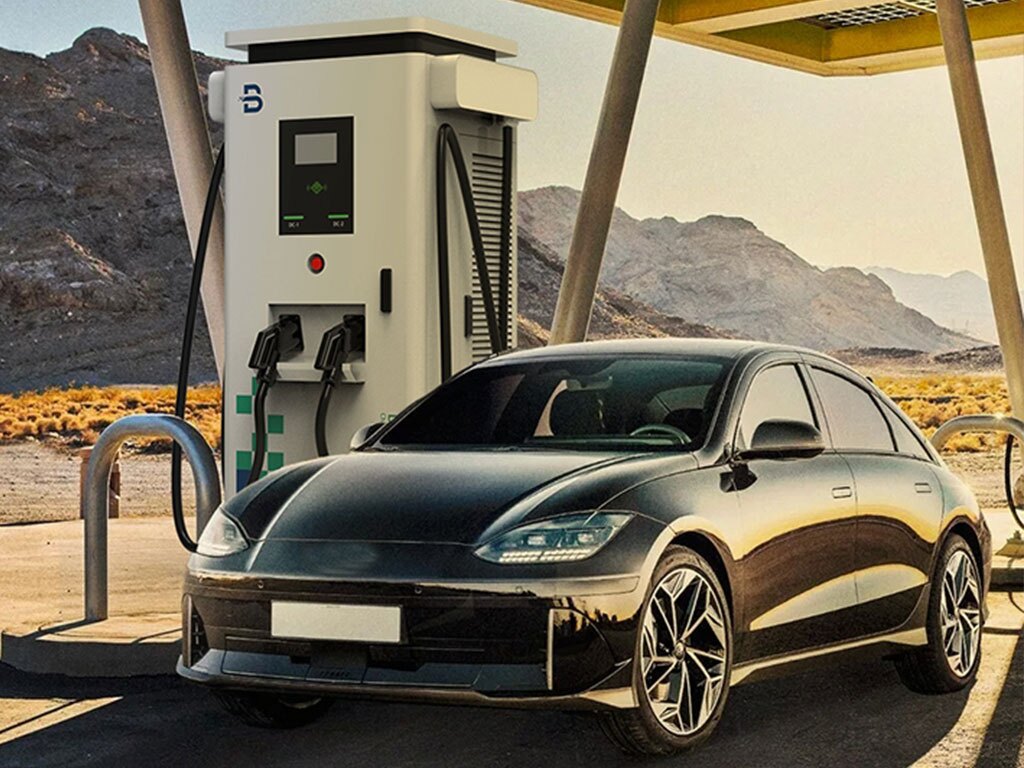

- EV Charging Stations: These control the power requirements of an electric fleet. In addition to mere charging, more sophisticated bi-directional chargers can convert the vehicle fleet into a power reserve. This enables the batteries of the vehicles to release energy to the building, which is a vital source of power when the grid is down or to prevent the high cost of electricity during peak demand times.

- Combined Heat and Power (CHP) Systems: CHP systems are very efficient and produce both electricity and useful heat using one fuel source, which makes them suitable in facilities with continuous thermal requirements.

- Wind Vortex Turbines: This is a bladeless wind power generator that generates electricity through the wobbling or oscillating movement of wind. It is silent and compact, and therefore, a perfect solution to supplemental power generation in urban or ecologically sensitive areas where conventional turbines cannot be used.

Applications of Front of the Meter

FTM projects are large scale assets that sell power into the grid, and are concerned with bulk generation and system-wide stability, as opposed to the needs of a single user.

- Utility-Scale Solar & Wind Farms: These are large solar panel installations (solar farms) or large collections of wind turbines (wind farms) that produce huge quantities of energy to be sold on the wholesale electricity market.

- Large Standalone BESS: Large-scale battery projects that are not coupled to a particular generator. They are mainly used to deliver the necessary grid services, including frequency stabilization, blackout prevention, and shifting of cheap renewable energy to peak demand periods.

- Conventional Power Plants: This type encompasses the traditional natural gas, hydroelectric and nuclear plants. They form the backbone of the grid, delivering reliable baseload and dispatchable power that can be switched on or off to respond to system-wide demand at any time.

The Critical Benefits of Front-of-the-Meter Systems

Although the BTM solutions are becoming more prominent, the FTM projects are still the backbone of the public power grid. They are systemic in their advantages and provided on a scale that cannot be matched by distributed resources.

Massive Scale, Lower Costs

The major benefit of FTM projects is the economic concept of economies of scale. The FTM developers can reduce their Levelized Cost of Energy (LCOE) by a factor of 10 or more by buying components in bulk, standardizing engineering designs, and streamlining construction logistics across hundreds of megawatts, compared to smaller, custom BTM projects. The reduced generation cost eventually translates to reduced wholesale electricity prices to the benefit of all consumers on the grid.

Ensuring Grid Stability

The main instrument that grid operators use to maintain system-wide stability and reliability is large, centralized FTM power plants. FTM assets that are dispatchable, like natural gas plants or large battery storage facilities, can be ramped up or down in seconds to react to sudden changes in supply or demand. They supply vital ancillary services, including frequency regulation and voltage support, which are vital to ensuring the technical parameters necessary to keep the grid running without collapsing.

Maximum Climate Impact

To meet ambitious state and national decarbonization targets, FTM renewable energy projects are critical. Although individual BTM systems help to decrease emissions, a single large FTM solar or wind farm can offset hundreds of thousands of tons of CO2 per year. It is the deployment of these utility-scale projects that makes a difference in climate change, enabling entire regions to shift their energy mix away from fossil fuels in a real and quantifiable way.

The Tangible Benefits of a Behind-the-Meter Approach

For businesses, contractors, and integrators, the BTM approach offers a powerful suite of benefits that directly address on-site operational and financial objectives.

Energy Cost Optimization

The first and the most obvious advantage of BTM is the possibility to manage and minimize energy spending strategically. On-site generation of electricity allows a facility to save on the cost of buying retail power at high prices in the utility. Combined with energy storage, BTM systems can be an effective means of reducing peak demand charges, which may represent more than 50% of a commercial electric bill. This is done by shaving the load of the facility by using stored energy during the short high-demand periods as measured by the utility.

Energy Independence and Safety

BTM systems offer an essential energy resilience and energy security. In facilities where power loss may result in catastrophic losses, e.g. data centers, manufacturing plants, or healthcare facilities, a BTM solar-plus-storage system can serve as a microgrid. In the event of a grid outage, the system is able to island itself off the grid and keep the critical loads of the facility running, maintaining business continuity and safety.

Sustainability Advancement

In a time when corporate responsibility is the most important, BTM renewable energy generation systems are a very visible and efficient means of a business to reduce its carbon footprint, meet its Environmental, Social, and Governance (ESG) objectives. On-site solar is a visible sign of sustainability commitment, which can boost brand image, appeal to environmentally-minded customers and employees and meet investor expectations of climate action and reductions in greenhouse gas emissions.

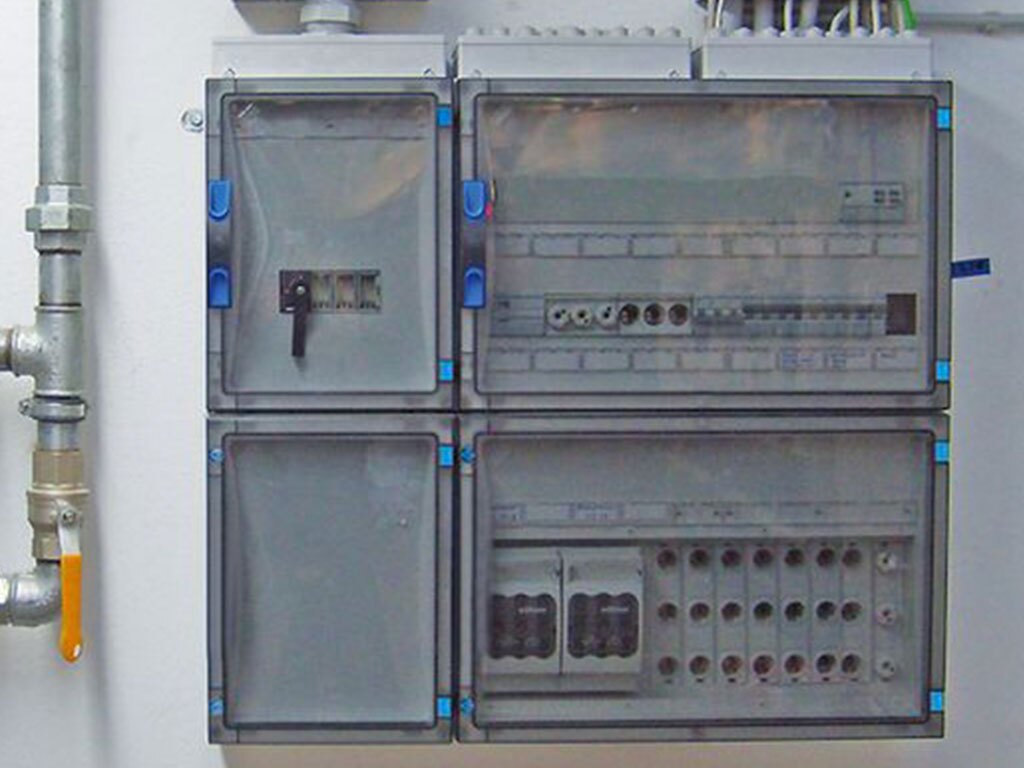

Regulatory Compliance

Regulatory environment is a key factor in any BTM project. To be successfully deployed, it must be done in strict compliance with local interconnection standards, electrical codes (such as the NEC), and equipment safety certifications (such as UL standards). Although this is a challenge, the use of high quality, certified components will result in a smoother, faster and safer permitting and commissioning process, without the costly delays and long-term integrity of the installation.

Power Quality Enhancement

In facilities that have sensitive electronic equipment, e.g. advanced manufacturing or medical imaging, power quality is as critical as power availability. Sags, swells, and harmonic distortions can occur in grid power. A BTM system with an advanced power conversion system (inverter) and battery storage can be used as a buffer, cleaning up the incoming power and delivering a pure, stable sine wave to critical equipment, thus avoiding damage and operational errors.

Load Management

BTM systems enable facility managers to become active energy managers instead of being passive consumers. They can actively manage the load profile of the facility by taking advantage of on-site generation and storage. This enables them to move energy use out of high-cost times (as determined by Time-of-Use rates) to low-cost times, a process called energy arbitrage, further optimizing energy expenditure.

Energy Data Visualization and Optimization

The current BTM systems are equipped with advanced energy management systems (EMS). Such platforms offer detailed, real-time information about energy production, use, and storage. This data visualization is not only used to monitor, but also to give the actionable intelligence required to constantly optimize performance, find additional savings opportunities, and perform predictive maintenance on system assets.

Tapping into the EV Charging Boom

The fast spread of electric vehicles is a huge challenge and a great opportunity. A large number of EV chargers can generate huge new electrical demand, making demand charges prohibitively expensive to a business. The solution is provided by BTM. Combining on-site solar and storage with EV charging infrastructure, a business can produce its own clean transportation fuel, store energy to smooth the grid during peak charging periods, and thereby avoid crippling demand charges. To PV and BESS contractors, this integrated ”solar + storage + EV charging” solution is a compelling value offering to clients interested in electrification in a sustainable and cost-effective manner.

From Benefits to Reality: Secure Your BTM Investment with Beny’s Technology

Beny offers advanced, reliable, and flexible energy storage solutions for both residential and commercial sectors, backed by over 30 years of R&D experience in electrical and solar protection products.

- Residential Storage: Optimizes solar energy usage, reduces electricity costs, and provides emergency backup during power outages. When combined with solar panels, it forms a microgrid, minimizing reliance on the main grid.

- Commercial & Industrial Storage: Peak shaving, reducing operational costs, and stabilizing fluctuations from renewable sources like solar. It ensures uninterrupted power for critical facilities, such as hospitals and data centers.

- EV Charging Stations: Ideal for areas with limited grid capacity or where off-peak electricity pricing is available, enabling cost-effective and efficient charging with dynamic load balancing and clean energy prioritization. One of Beny’s advanced technologies is energy-storage-enabled charging stations that integrate large-capacity batteries with DC fast chargers, forming a compact “storage + fast charging” hub that solves grid expansion challenges and reduces operating costs.

- Efficient & Durable: Features advanced liquid/air cooling systems, long battery life (up to 8000 cycles), and deep discharge (up to 90%) for maximum energy utilization.

- Flexible & Smart: Modular design for easy installation and expansion, compatible with various inverters, with real-time monitoring and remote management.

Beny provides comprehensive solutions from design to support, ensuring reliability and efficiency from day one. To learn how Beny’s advanced components can de-risk your next project and enhance its performance, contact our engineering team for a consultation or explore our detailed product specifications today.

Key Trends Shaping the Future of BTM and FTM

Looking ahead, Front-of-the-Meter (FTM) and Behind-the-Meter (BTM) systems will have more specialized and advanced roles. This transition is building a dynamic and robust energy infrastructure where both sides of the meter have different but complementary roles.

Front-of-the-Meter (FTM) Trends:

The primary trend in FTM is the enormous addition of utility-scale energy storage to create a more robust and flexible grid. This is occurring in two important ways:

- Standalone Battery Projects: Massive battery systems, like the Moss Landing Energy Storage facility, are being deployed to store excess renewable energy and can be used to provide immediate grid stabilization when needed.

- Co-location with Renewable Generation: Energy storage is currently being co-located with renewable generation sources such as solar or wind farms. This arrangement enables the energy produced to be stored and discharged in a controlled way, making renewable energy sources more reliable and dispatchable source of power to the grid. This ”self-storage” ability makes the grid always have a constant supply of renewable energy, which is prepared against any eventuality.

Behind-the-Meter (BTM) Trends:

Meanwhile, Behind-the-Meter (BTM) systems are developing. The initial installations of simple solar are evolving into a more intelligent energy ecosystem. It is about the combination of solar, battery storage, and EV chargers into a single system, which is controlled by an Energy Management System (EMS).

This transition has a number of important advantages:

- Reduction of waste and optimization of energy use to save costs.

- Resilience to outages via backup power, so that operations can continue.

- Electric vehicles have low-cost, on-site charging, which makes them less dependent on external energy sources.

Such combined systems do not only reduce the costs of operation but also contribute to the increasing demand in electrified transportation, creating new opportunities to generate value.

The Intersection: Virtual Power Plants (VPPs)

The most transformativetrend is the development of Virtual Power Plants (VPPs) that integrate thousands of smart BTM systems into one, unified resource. This model enables grid operators to call on these distributed resources when they are required. The advantages are two-fold:

- To BTM owners: They will be able to enter energy markets and create new sources of revenue.

- In the case of the grid: VPPs provide a distributed, flexible source of power that can be depended upon at any time, and the distinction between energy production and energy consumption becomes blurred.

Final Thoughts

The choice of a Behind-the-Meter or a Front-of-the-Meter approach is essentially a strategic objective question. FTM is still the realm of large-scale, centralized power generation that is needed to stabilize and decarbonize the public grid. BTM, however, is the empowerment of the energy consumer, and it provides a direct route to cost savings, resilience, and sustainability to businesses and organizations. To the professionals designing and implementing these BTM systems, the road to concept to successful operation is lined with quality. The final success of this energy transition does not only depend on visionary strategies, but also on the engineering excellence and uncompromising reliability of all components on both sides of the meter.