Solar Disconnect Explained: Types, Selection & Installation Tips

Share this article in Social Media:

- Home

- Solar Disconnect Explained: Types, Selection & Installation Tips

What is a Solar Disconnect and Why Is It Critical

A solar disconnect is a switch at its most basic level. A manual, simple switch. It does not work in a subtle way: it literally cuts the power flow between two points. It is not so difficult, but rather where it is located and why it is required. The ‘why’ is an issue of deep safety. Direct current (DC) is produced as soon as solar panels are exposed to light. The sun does not have an ‘off’ button. This unceasing production poses a great and enduring threat.

Think of the firefighter from the local fire department on a roof, trying to ventilate a burning building. Think of the technician who is repairing an inverter. Think about the utility lineman on a transformer on the street. All these people need to have a sure, verifiable, and reachable way of de-energizing the circuits they are going to touch. A solar disconnect offers that. It is an uncompromising element of maintenance, a first line of defense in a case of emergency like an event of a fire, and a compulsory element of any system to be considered compliant by an Authority Having Jurisdiction (AHJ) and to meet local regulations.

It is not a matter of convenience but of complete control. These devices are required by the National Electrical Code (NEC), especially in Articles such as 690.13 and 690.15, which are very specific. The main force is the principle of electrical isolation. A technician should be capable of opening a switch manually, locking it in the ‘off’ position (a procedure called Lockout/Tagout or LOTO) and continue working with the knowledge that the circuit is dead. In the absence of this, each solar array is a high-voltage live hazard at all times. It is not a design oversight that it lacks; it is a design failure of the utmost.

Understanding the Two Main Types: AC Disconnect vs. DC Disconnect

‘Solar disconnect’ is a confusing term since it is not a single device. It is defined as two or more, essentially different elements that cannot be used interchangeably. The inability to differentiate between them is a widespread and dangerous mistake. The inverter is the dividing line, the device that converts the DC power of the panels into AC power to your home or the grid. There is a disconnect on the DC side (prior to the inverter), and there is a disconnect on the AC side (after the inverter). They cannot be used interchangeably.

| Feature | AC Disconnect | DC Disconnect |

|---|---|---|

| Other Names | Grid-Side Switch, Utility Disconnect | PV Isolator, Array Disconnect |

| System Location | Located after the inverter (between inverter and utility grid/meter); typically installed outdoors near the utility meter or main service panel | Located before the inverter (between solar panels and inverter); typically installed near the inverter or PV array input |

| Main Purpose | Protects the utility grid and personnel by preventing backfeed current (anti-islanding) | Protects equipment, technicians, and firefighters by isolating high-voltage DC from solar panels for safe maintenance |

| Switch Design & Characteristics | Standard heavy-duty AC switch with zero-crossing capability, easy to interrupt current | Purpose-built DC switch with internal arc suppression to safely break high-voltage DC current |

| Certification Standards | UL 98 or equivalent AC service-rated certification | UL 508i / IEC 60947-3 or equivalent DC isolator certification |

AC Disconnect: The Grid-Side Safety Switch

The AC disconnect is installed after the inverter, between the inverter and the main service panel of the building or, more frequently, the utility meter. It does not benefit you, but the utility company, as its main beneficiary. When a lineman has to fix the grid, they must be sure beyond any doubt that your solar system, which is technically a miniature power plant, is not back-feeding electricity onto the lines that they is working on. This is an incredibly dangerous effect known as islanding, in which your system is still energizing a so-called ‘dead’ grid. Their safety switch is the AC disconnect. It is nearly always a heavy duty, lockable switch in a weatherproof enclosure. Utility regulations usually require it to be installed in a place that is immediately available to their staff at all times, which usually is on an outside wall close to your main electrical meter. It has technical specifications that depend on the AC output of your inverter, and is a fairly simple device, like other AC service-rated switches.

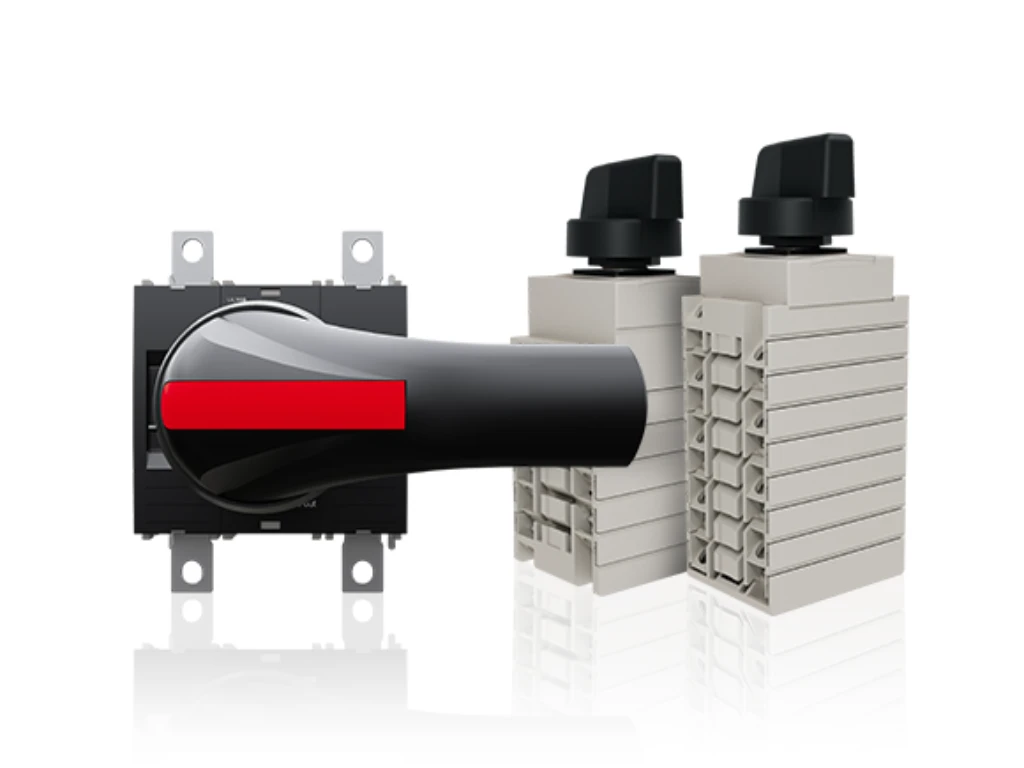

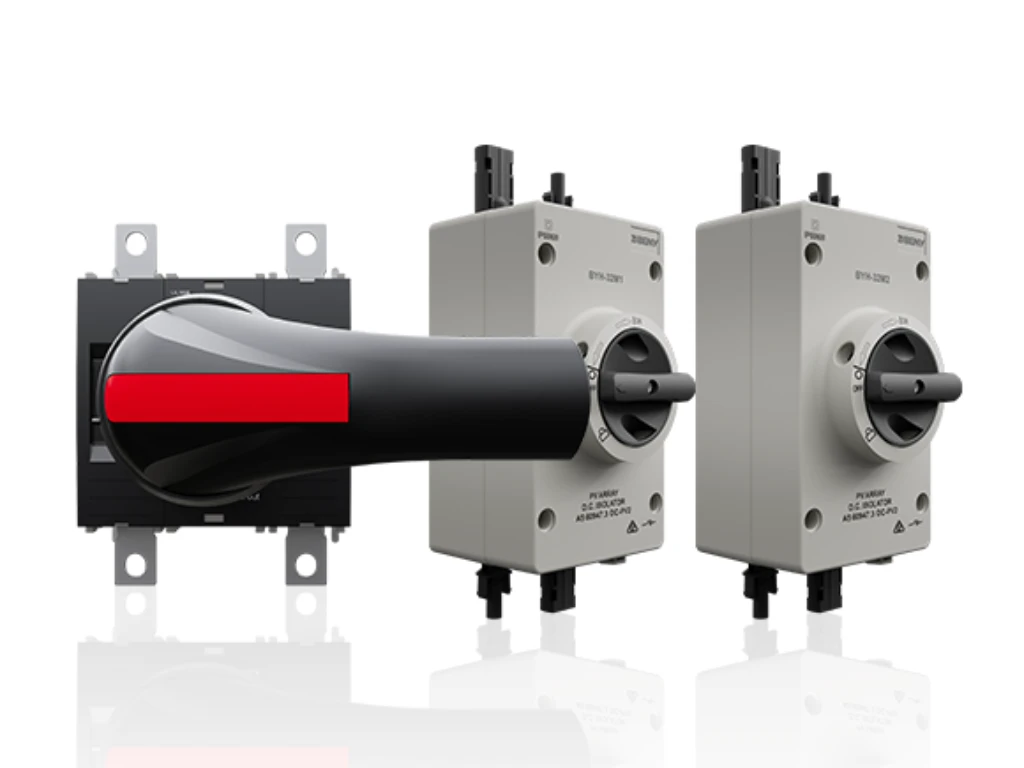

DC Disconnect (PV Isolator): The Array-Side Safety Switch

The DC disconnect, also known as a PV isolator or array disconnect, is on the opposite side of the inverter. It is placed between the solar panels themselves (the array) and the DC input of the inverter. It is there to serve a completely different purpose: to safeguard the equipment and the technician who is working on it. To service, repair, or replace a central inverter, it is necessary to be able to isolate it with the high-voltage DC power supplied by the roof. This is a difficult task technically, since it is much more difficult and dangerous to interrupt high-voltage DC power than it is to interrupt AC. DC power, particularly at the 600 V to 1500 V typical of modern arrays, does not desire to be interrupted. In contrast to the sine wave of AC, which crosses the zero volts 120 times per second (which, of course, extinguishes an arc), DC is a continuous, inexorable flow of power with no ‘zero-crossing’ point to facilitate this interruption. Breaking a live high-voltage DC circuit thus forms a sustained high-temperature plasma arc. That is why the significance of high-quality, purpose-built DC isolator switches cannot be overestimated. It has to be a very specialized item of engineering, carefully designed to take the unremitting high-voltage DC power, and constructed with internal arc-extinguishing devices to put out this hazardous arc in a safe and quick manner. Placing an AC-rated switch in this location is a formula of disastrous failure; the switch will tend to weld itself together, melt, or even blow up when it is loaded.

How to Select the Right Solar Disconnect for Your System

The choice of a disconnect is not an approximation. It is an accurate estimation of the non-negotiable requirements of your array and the needs of your environment. Making the wrong decision is not a minor error; it is the design of a system that does not work or one that breaks down in a spectacular manner when put to the test. It is a systematic checklist and not a guessing game.

Calculating the Voltage Rating (Voc)

First, voltage. The switch should be rated to the maximum voltage that your array can produce. This is not the operating voltage (Vmp) but the Open-Circuit Voltage (Voc) which is listed on the data sheet of your solar panel. To obtain your string Voc, you have to add the Voc of all the panels in one series string. But this is not all. The voltage of photovoltaic panels rises with the drop in temperature. The NEC requires a calculation of temperature correction (NEC Table 690.7) depending on the lowest anticipated ambient temperature at your installation site. This cold-weather, adjusted Voc is your lowest possible voltage requirement. A nominal 600 V array in a cold climate can easily be above 700 V, and requires a 1000 V rated switch, not a 600 V one. No compromise is possible here, under-rating the voltage is a major fire risk.

Determining the Amperage Rating (Isc)

Second, amperage. The switch should be rated to be able to withstand the maximum current that it may be exposed to. This is based on the Short-Circuit Current (Isc) of your solar strings. When you have several strings in parallel (e.g. in a combiner box), you need to add the Isc values. Since solar circuits are regarded as a source of power that is of continuous duty (that is, can be used at full power at least three hours or longer), the NEC mandates that a 1.25 (125%) safety factor be applied to the maximum circuit current. The amperage rating of your disconnect should be no less than 125 percent of the calculated maximum current. This is not a ‘suggestion.’ Prevention of overheating, component degradation, and fire is a basic requirement.

Fused vs. Non-fused: Which Do You Need?

This option is determined by the design of the system and the location of overcurrent protection (OCPD).

- Non-fused Disconnect: This is a basic on/off switch. It does not offer any overcurrent protection. It is applied with the sole purpose of isolation. This is suitable in case the OCPD is offered elsewhere. As an example, a DC disconnect of a single-string string inverter is frequently non-fused, because the inverter itself provides the required protection.

- Fused Disconnect: This is a type that has fuses built into the switch enclosure. It offers overcurrent protection and isolation. This is necessary in systems that have three or more parallel strings that feed into a combiner box. The strings should be fused separately to ensure that they are not subjected to reverse current by the other strings in case of a fault. Between a battery bank and an inverter, a main fused disconnect might be needed too.

Do not think that one is always superior; they are used in different design purposes.

Selecting the Correct Enclosure (NEMA/IP Rating)

The internal parts of the switch are of no use when the box that houses them collapses. In North America, the enclosure is rated by NEMA (National Electrical Manufacturers Association), or internationally by IP (Ingress Protection).

- NEMA 3R: This is the minimum of most outdoor installations. It is resistant to weather and it keeps off falling rain and sleet.

- NEMA 4 / 4X: This is a big improvement. NEMA 4 is watertight, i.e. it is resistant to hose directed water. This is essential in regions where the rain is blown by the wind or where the equipment may be sprayed. The 4X provides corrosion resistance and is therefore necessary in coastal, industrial or agricultural applications.

- IP Ratings: IP65 is dust-tight and resistant to jets of water. IP66 is resistant to high-power water jets. These are typical international equivalents of NEMA 4-style protection.

The enclosure is determined by the environment. When selecting an indoor-rated (NEMA 1) enclosure to be used in an outdoor environment, the enclosure will fail quickly due to water intrusion.

Meeting Code & Certification Requirements (NEC, UL, IEC)

Lastly, there is no specification that is important when the device is not certified by a Nationally Recognized Testing Laboratory (NRTL). This certification is your sole independent guarantee that the switch will actually operate to its rated fault conditions. In the US, this involves seeking a UL mark (e.g. UL 98 or UL 508). In Europe, it implies IEC compliance and a CE mark. A huge liability is an unlisted, non-certified component. It will not pass your electrical inspection, will probably cancel your property insurance, and is a deep and unacceptable speculation on the safety of your system. It is among the most inappropriate places to attempt to save money.

As you will notice, the choice of the appropriate disconnect is not just a matter of basic ratings. Non-negotiable are certification and safety features, in particular. A properly designed DC isolator should be able to suppress arc quickly and be absolutely reliable when loaded. Here professional DC protection manufacturers such as BENY put their specialized knowledge into practice.

Need a DC Isolator That Actually Works Under Load?

Common Solar Disconnect Installation Mistakes to Avoid

Theory is elegant. Practice is messy. An otherwise well chosen disconnect may be rendered useless, or even actively dangerous, by a thoughtless installation. The criteria are demanding because of a reason. The following are the most prevalent, and preventable, failures.

- Reversed Polarity (DC Disconnects): This is probably the worst and most dangerous mistake. The ‘Line’ and ‘Load’ terminals are not recommendations on a DC isolator switch. The power source (the solar panels) should be connected to the ‘Line’ side. The device (the inverter) should be connected to the ‘Load’ side. This is due to the fact that the arc-extinguishing mechanism of the switch is directional. Inverting the polarity nullifies this important safety measure, virtually ensuring that the switch will weld itself closed or will fail disastrously when loaded.

- Inappropriate Location and Accessibility: The NEC requires disconnects to be ”easily accessible”. This does not imply available with a 20-foot ladder and a map. It is in easy access, not obstructed by equipment and visible to a first responder or technician. Do not conceal your disconnects in an attic, in a crawlspace, or behind a bolted panel. In the case of utility AC disconnects, consult local utility regulations, which nearly always require a designated outdoor position close to the meter.

- Incorrect Conductor Torque: The terminal lugs in a switch have a certain amount of torque in inch-pounds printed on their side or in the installation manual. ‘Good and tight’ is not a technical specification. Too loose and you make a high-resistance point; this point will produce a lot of heat, melt the insulation and begin a fire. Excessively tight, and you cut the strands of the conductor and the lug itself, which will also cause a high-resistance failure. Apply a calibrated torque wrench. Every single time.

- Application of AC-Rated Components in DC Applications: This needs to be repeated, as it is the most fatal mistake of the amateur. A DC circuit breaker or switch, particularly high-voltage PV, cannot be operated on an AC-rated circuit breaker or switch available at a home improvement store. It does not have the means to put out a DC arc. It will not work. It will not work, and it will probably ignite a fire. Only components with DC voltage and current ratings and certifications should be used.

- Weak Enclosure Management: NEMA 4X enclosure will be useless when you drill your conduit entry holes on the top and funnel the water directly on the terminals. Conduit entries should always be planned on the sides or better still the bottom. Make sure that all hubs and fittings are NEMA-rated and well sealed.

Conclusion

The solar disconnect is, after all, a complex device with simple rules. It is not an appendix, nor is it a part where angles may be cut. It is the main protector of safety of your system, your property, and the staff that has to deal with it. Since the difference between the AC and DC types is obvious and the calculation of voltage and amperage requires strictness, the only way that is acceptable is diligence. The requirements of the NEC and UL are not red tape; they are the condensed wisdom of experience, and it has been learned, too often at a very high price. Treat them as such.

FAQs

🔌 What is the difference between a solar disconnect and a circuit breaker?

A disconnect (or isolator) is a manual load-break switch used only for isolation—it won’t auto-trip on overcurrent. A circuit breaker gives both manual and automatic protection, opening instantly when it senses a fault. Every breaker can isolate, but not every disconnect can break faults.

⚡ Does my solar system need a rapid-shutdown device AND a disconnect?

Yes. The manual DC disconnect lets technicians safely isolate equipment for service, while the rapid-shutdown system (NEC 690.12) automatically drops rooftop conductors below 80 V in 30 s for fire-fighter safety. They serve different roles and work together.

🔧 Can I use a “combiner box” as my DC disconnect?

Usually, yes. Modern combiner boxes often integrate a main DC disconnect (plus string fusing when needed) into one enclosure. Just confirm the switch meets the full array voltage, current and certification requirements.

📍 Where is the DC disconnect usually located?

NEC requires it to be “readily accessible.” Typically it’s at the PV array DC entry point into the building, or built into the inverter itself. If the inverter is indoors, mount the disconnect just outside the point of entry or on an exterior wall.

🏠 Can you legally disconnect from the grid?

Building a new off-grid system is generally legal once it passes local codes. Severing an existing grid-tied home is far more complex and utility-specific. Either way, approved DC isolators and other safety gear remain mandatory.

© 2025 Solar Disconnect Guide – Professional PV Safety Solutions