NACS vs J1772: 2026 Deep Comparison and Buying Guide of EV Charging

Share this article in Social Media:

- Home

- NACS vs J1772: 2026 Deep Comparison and Buying Guide of EV Charging

When it comes to existing charging infrastructure, there are times when technical elegance ultimately overcomes the legacy momentum. The North American electric vehicle charging market has reached such a crossroad as we head into the landscape of 2026. The Plug War that defined the early 2020s is practically over, resulting in the widespread adoption of a unified standard. What is left is a transition- a move towards the past, multi-part standards to a single, integrated future of ev charging.

To the contemporary EV owner or commercial fleet manager, the decision between the North American Charging Standard (NACS) and the SAE J1772 (also known as Type 1) is no longer a question of philosophical discussion, but one of economic and operational fact. This guide offers an in-depth look at these main connector types, including the reason why NACS, which is now codified as SAE J3400, is the architectural choice of the coming decade of mobility.

What is NACS?

The North American Charging Standard (NACS) has transformed the EV experience as a streamlined interface that combines both ac charging and DC charging into one, small port.

It was originally created by Tesla in 2012, and its sole purpose was to develop a connector design small enough for effortless ease of use by consumers but powerful enough to be used in high-speed fast chargers. For a decade, it remained a proprietary supercharger network and a walled garden for tesla vehicles. In late 2022, however, Tesla released released the technical information report and specifications publicly, causing the SAE to proceed at a pace never seen before to formalize the design as SAE J3400 by 2024. This move ensured the widespread availability of the standard across the continent, leading to the rapid expansion we see today.

This development has changed NACS into a brand-specific luxury to a public utility. By 2026, NACS is the native port of a wide range of electric vehicles sold in North America, a move towards a one-plug-to-rule-them-all ecosystem. Its standout features include native access to the supercharger stations and better ergonomics since the plug is much lighter and easier to manipulate than its predecessors.

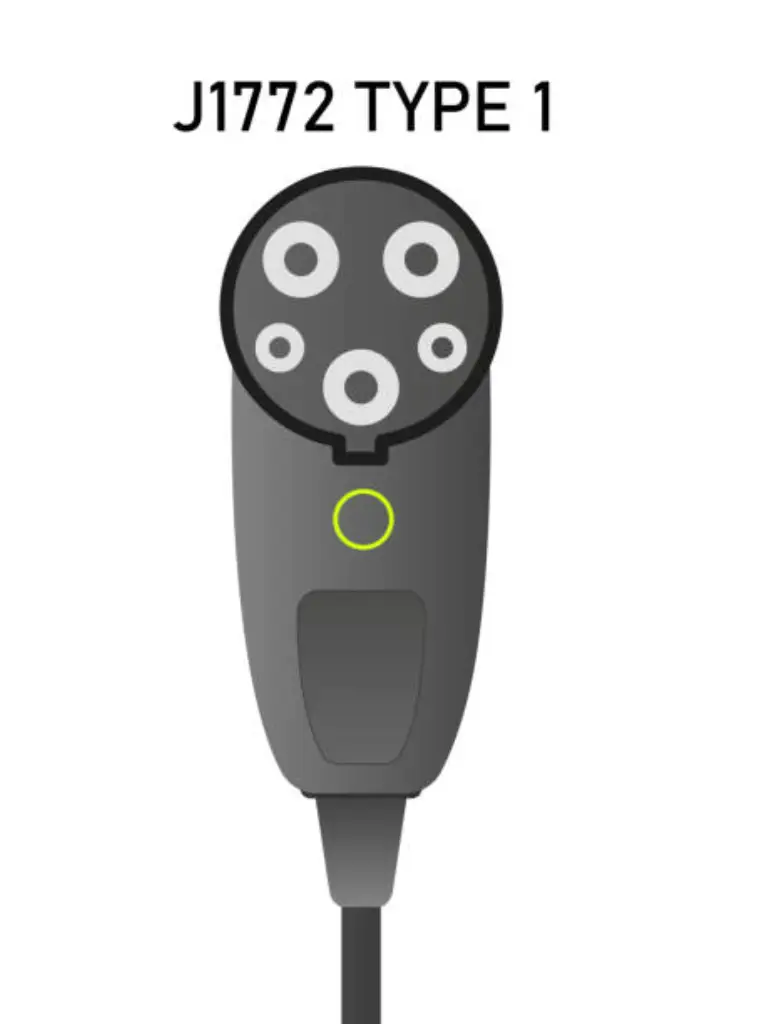

What is J1772?

The first pioneer in the industry was SAE J1772 (Type 1), which was the conventional AC standard of non-Tesla EVs during more than ten years.

It was developed by the SAE in the late 2000s, and was intended to offer a safe, standardized method of supplying Alternating Current (AC) to the first generation of EVs such as the Nissan Leaf and chevrolet volt. Although it was successful in its mission as a universal port in Level 2 charging, it later turned out to be a bottleneck as the industry shifted toward rapid expansion of DC needs.

J1772 is quickly entering the legacy stage today. As electric vehicle manufacturers switch to NACS, the J1772/ccs connectors combination has become a liability. Since J1772 was originally AC-based, it was physically modified with two large DC pins to form the Combined Charging System (CCS1). This led to a heavy, cumbersome interface that lacks the physical durability of modern designs. To contemporary designers, the sheer size of the CCS1 inlet makes vehicle aesthetics difficult and the space behind the bodywork to be excessive, rendering it outdated in a NACS-dominated market.

Main Differences: NACS vs. J1772

In order to see the reason why the market has undergone such a significant impact, we need to look at the raw data. The differences in the design of its connector and technical capability are pointed out below.

NACS (SAE J3400) vs. J1772/CCS1 Comprehensive Comparison Table

| Category | Comparison Metric | NACS (SAE J3400 / Tesla) | J1772 (Legacy / Type 1) |

|---|---|---|---|

| 1. Physical & Technical Specs | Size & Usability | Approximately half the size and much lighter; made to be operated with one hand easily. | Large and heavy; has a sticking out manual lock; difficult to use with one hand. |

| Pin Architecture | Integrated Design: 5-pin miniature design with primary pins shared between AC and DC. | AC Only Native: DC needs two huge extra pins (CCS1), which makes it a 8-shape design, a Frankenstein. | |

| 2. Performance & Intelligence | Charging Type | Universal Integrated: One physical interface supports AC (Level 2) and DC Fast Charging. | Single-Purpose AC: Native J1772 is AC-only; DC charging is possible with the large CCS1 combo extension. |

| Charging Speed | Extreme/Full Speed: Optimized to the maximum pressure DC fast charge allowed by the station. | Slow/Medium Speed: This is mainly limited to AC speeds to charge overnight or at the destination. | |

| Max Power Output | Theoretical ceiling of 1MW; 250kW+ current DC; 19.2kW current AC. | Limited to 19.2kW (80A/240 V) AC; will not produce DC without the CCS1 physical modification. | |

| Comm. Protocol | PLC (Power Line Communication): ISO 15118 based; natively supports “Plug & Charge”. | PWM (Pulse Width Modulation): Simple analog signal; restricted to simple handshakes and current limits. | |

| V2G/V2H Potential | Native Ready: Digital PLC is bidirectional power flow (Vehicle-to-Grid/Home). | Limited: Analog legacy hardware needs complicated external workarounds to be bidirectional. | |

| 3. Business & Economics | Commercial Voltage | Native 277 V Support: Directly connects to commercial 480 V 3-phase power (277 V per phase) without transformers. | 240 V Limit: Commercial applications need costly, cumbersome step-down transformers. |

| Hardware Cost | Reduced System Cost: Makes vehicle inlets, wiring harnesses, and site infrastructure simpler. | Increased Cost: Unnecessary pins, heavier cables and independent AC/DC logic add to the cost of manufacturing. | |

| 4. Reliability & Environment | Durability & Lifespan | High Reliability: The car has an internal locking mechanism; the plug is a solid-state block that does not have any moving parts. | Moderate: External plastic latch is likely to suffer a case of metal fatigue or snapping when dropped. |

| Climate Resilience | Excellent: Flush design and no external crevices; resistant to ingress of ice and freezing. | Poor: External latches often become frozen in the north, making them useless. | |

| Vehicle Packaging | Minimal Footprint: Small inlet can be fitted into tail-lights or narrow fender space. | Large Footprint: This needs a huge, strengthened mounting surface, which determines the styling of the vehicle. | |

| 5. Strategic Roadmap | Market Position | 2026 Industry Standard: Major North American OEMs have fully adopted; the End-State of the charging war. | Legacy Standard: Moving to secondary use of older vehicles and simple home AC cases. |

Physical and Technical Specifications

- Size & Usability (Size vs. Substance):

The NACS connector is an ergonomics masterpiece, approximately half the size and much lighter than the J1772/CCS1 combo. The J1772 handle is heavy industrial, but the overall charging process is designed to be performed with a single hand, which is an important accessibility feature to older drivers or those with limited mobility. - Pin Architecture:

NACS has a 5-pin design, compared to the Frankenstein architecture of CCS1, which connected two large DC pins to a 5-pin AC base, forming a proprietary charging connector feel, which is mechanically complex. The main pins are identical and may be utilized in both AC and DC, and a streamlined port may be utilized which does not take up much bodywork space.

Performance & Intelligence

- Type of Charge: NACS is a universal integrated interface. A single port can charge home AC and charging ultra-fast DC. By 2026, the gold standard of reliability, tesla chargers, will be available to the users without any special effort. Although these can be used by rest of the evs (legacy cars) through adapters, the native NACS experience is much smoother. J1772 is single-purpose AC in nature and the CCS1 extension is bulky even to allow high-speed charging.

- Charging Speed: NACS allows for extreme speeds at supercharger stations. J1772/CCS1 is commonly a bottleneck, designed to support a slower rate of destination charging, but not high-throughput transit.

- Max Power Output: The difference in performance is insignificant in the case of overnight home charging. Both standards are limited to 80 amps (19.2 kW). When you are charging in your garage, the speed is the same; J1772 is a dead, limited to 19.2kW of AC, but NACS is future-proofed. It already has 350kW+ and has the thermal capacity to achieve 1MW in heavy-duty trucking.

- Communication Protocol (Analog vs. Digital): J1772 uses PWM (Pulse Width Modulation), a simple analog handshake. NACS is also natively configured to support PLC (Power Line Communication) and the ISO 15118 protocol, allowing car and grid to talk at high speed in a digital conversation.

- Bidirectional Potential (V2G/V2H): With the transition to a decentralized grid, the capability of a car to charge a home (V2H) or assist the grid (V2G) is necessary. NACS is energy decentralization native. Its digital backbone manages the complicated data of Vehicle-to-Grid (V2G) and Vehicle-to-Home (V2H) without much hardware workaround, but J1772 needs a lot of hardware workaround.

Business & Economics

- Commercial Voltage Support (The 277V Advantage):

This is the secret killer feature of NACS (J3400). The commercial buildings in the united states are generally powered by three-phase 480 V, which supplies 277 V per phase. J1772 chargers that are older do not support 277 V and need costly and bulky step-down transformers. NACS chargers are hardwired to 277 V, meeting the growing demands of property owners, which simplifies installation by approximately 15-20 percent and saves thousands of dollars in equipment. - Hardware Cost:

NACS provides a lower system-level cost to both manufacturers and site hosts by simplifying vehicle inlets, wiring harnesses, and removing redundant pins and transformers, compared to the high cost of manufacturing legacy standards, addressing the growing needs of electric vehicle owners for affordable home and public solutions.

Reliability & Environment

- Durability & Lifespan (Latch vs. Lock): The external plastic latch of J1772 is the weakest point, as it is often broken or worn out. NACS relocates the locking mechanism within the vehicle, and the plug is a solid-state block with no moving components, which significantly extends its life.

- Climate Resilience: J1772 latches are infamous with freezing in the north. NACS has an internal locking mechanism with no external crevices, which is immune to ice jams and can be used in sub-zero temperatures.

- Vehicle Packaging (Aesthetics): The small size of the NACS inlet provides designers with complete flexibility, enabling it to be installed in narrow spaces such as built-in tail-light assemblies. Legacy J1772 has huge, reinforced mounting spaces that determine and frequently impede styling of vehicles.

Strategic Roadmap

By 2026, NACS is established as the North American Industry Standard. Large OEMs have shifted to this ecosystem due to its high ROI and future-proofing, abandoning J1772 as a Legacy standard that is mostly used to support older vehicles.

2025-2026 Transformation Roadmap: Strategies for Owners and Manufacturers

By 2026, NACS is established as the North American Industry Standard. Major automakers ford and GM have shifted to this ecosystem due to its high ROI and future-proofing, moving away from J1772.

Native NACS Integration 2026 Models

By 2026, the industry standard has been to construct upcoming ev models with a native NACS port. This hardware transition removes the use of large adapters and enables a smooth Plug and Charge experience for a diverse range of electric vehicles.

| Manufacturer | Key 2026 Native NACS Models | Primary Ecosystem Benefit |

|---|---|---|

| Ford | F-150 Lightning, Mustang Mach-E | Instant, adapter-free access to over 20,000 Supercharger stalls for ford evs |

| General Motors | Cadillac OPTIQ / OPTIQ-V, Chevrolet Bolt | The OPTIQ leads GM’s native migration, followed by the refreshed Bolt. |

| Hyundai | IONIQ 9, IONIQ 5 (2025-26) | Optimized for high-voltage V4 Superchargers with 800V architecture. |

| Rivian | Refreshed R1S, Refreshed R1T | Streamlined “adventure charging” across Tesla and Rivian networks. |

The Dual-Connector Strategy of Transition Models

Although the industry is shifting to a single-port future, a number of 2026 models use a bridge design. The most notable one is the 2026 Nissan Leaf, which uses a dual-port design: a J1772 inlet to charge at home using AC and a NACS inlet to charge at DC fast charging. The approach enables manufacturers to use existing chassis architecture and internal wiring harnesses without a complete platform redesign, but these vehicles are becoming more and more defined as transitional or budget-tier in the 2026 resale market.

Adapter Ecosystem of Cross-Network Compatibility

The owners of ev models or legacy vehicles manufactured prior to the 20252026 transition can retain their full utility by a dual-adapter approach. This makes sure that no vehicle is left stranded irrespective of the type of its native port.

| Non-Tesla Owners (J1772/CCS1) | Tesla & NACS-Native Owners |

|---|---|

| The Tesla supercharger stations is available to non-Tesla owners with a CCS1-to-NACS DC adapter. Some stations also feature the magic dock, a built-in adapter that allows any EV to use a Tesla stall. These are commonly offered as standard equipment by brands such as Ford and Rivian in 2026 to make sure that their older customers can use the 20,000+ high-speed stalls available. | Drivers can use a small J1772-to-NACS AC adapter to utilize destination chargers at hotels or older mobile connectors. This is a blue-chip that any EV glovebox needs, so that modern vehicles can charge on legacy infrastructure when staying overnight. |

Maintenance Cost Projection in the next 5 Years: J1772 or NACS?

Hardware Reliability and Mechanical Durability

The fundamental distinction between the long-term repair budgets of these two standards is reduced to their physical locking mechanisms. Since the J1772 standard uses an external plastic latch which is commonly regarded as the Achilles heel of the system, it is much more likely to fail than the solid-state NACS design.

The track record of NACS hardware is significantly better than J1772. In high-traffic areas like the bay area, public charging network statistics indicate that charging handles based on the J1772 standard are three times more likely to need replacement than those based on the NACS standard. Actually, the mechanical failure of the J1772 plug itself is the cause of about 40 percent of all station downtime. NACS is expected to provide a 70 percent decrease in the cost of handles repairs in five years by relocating the locking mechanism within the vehicle and eliminating the external trigger.

Economic Factors: Adapters and Asset Retention

To the users still using legacy ports, there is a recurring Adapter Tax that imposes a financial strain that increases over time and at the same time affects the market value of the vehicle.

Good quality NACS-to-J1772 adapters usually cost between 150 and 200 dollars. Nonetheless, these units normally require replacement after 24 to 36 months due to continuous physical wear, pin degradation, or just loss. In addition to these hardware expenses, there is a huge effect on resale. It is estimated that by 2030, cars with native NACS ports will be worth an additional $2,000 to $4,000 more than legacy models. The extensive compatibility of NACS makes it the safer financial bet for long-term ownership. With the full maturation of the infrastructure around the NACS standard, the depreciation of legacy vehicles will accelerate by 10-15 percent, and the cars that require adapters will become significantly less appealing to second-hand buyers.

Five-Year Operational and Financial Model

To accurately gauge the long-term implications of choosing between these competing standards, we must look beyond the purchase price and examine the total cost of ownership over a typical five-year operational cycle. The table below breaks down the critical financial and operational divergences between maintaining a legacy J1772 infrastructure versus investing in the native NACS ecosystem.

| Comparison Factor | The Legacy J1772 Path | The Native NACS Path | Five-Year Financial Impact |

|---|---|---|---|

| Repair frequency | High failure rates due to fatigue of the external plastic latch. | Near-zero failures thanks to a solid-state plug design. | 70% Savings on long-term hardware repairs. |

| Equipment fees | Cumulative costs of $400–$600 for recurring adapter replacements. | Minimal spending on a single compact adapter for legacy AC piles. | Saves ~$450 per vehicle in hidden equipment costs. |

| Resale and value | A 15% steeper loss in value as the system is classified as “Legacy.” | A premium market position with high demand as the industry standard. | +$2,000 to $4,000 preserved at the time of resale. |

| Network reliability | Frequent “Handshake Errors” caused by adapter friction or latch jams. | A 99% success rate on the first try with native integration. | Higher ROI driven by consistent station uptime. |

The decision to use NACS (J3400) today is a strategic decision to prevent inflation of maintenance in the future. Although a J1772 configuration may seem cheaper in the short run, the Adapter Tax plus 3x failure rate guarantee that the legacy path will be much more expensive in the first 30 months of operation.

Safety Warning: A Comprehensive Guide to Avoiding Pitfalls When Buying Power Adapters

The Importance of UL 2252 Certification

The UL 2252 standard will be the ultimate safety standard of electric vehicle coupler adapters in 2026. This certification guarantees that Any adapter used for fast chargers has been subjected to extreme flammability testing and intense thermal cycling to withstand the extreme loads of a 500A DC session. It is a serious risk to use an adapter that does not have this mark; Without proper ground fault protection and thermal monitoring, uncertified adapters can melt during high-speed sessions.

Adapter Performance and Thermal Comparison

The table below compares the top certified brands with generic ones according to the real-life thermal testing and electrical stability results.

| Adapter Brand / Category | Certification Status | Peak Thermal Load (48A AC) | Current Stability | Safety Architecture |

|---|---|---|---|---|

| Tesla Genuine / OEM | Fully UL 2252 Compliant | Exceptional (~100°F) | Near-zero fluctuation | Integrated Thermistors |

| Lectron Vortex Plus | UL 2252 Certified | Stable (~115°F – 120°F) | High (500A Rated) | Automatic Interlock |

| A2Z Stellar / Atom | UL 2252 Certified | Stable (~118°F) | High (500A Rated) | Dual Thermal Sensors |

| Generic / Uncertified | None or Basic UL 2251 | High (Exceeds 140°F) | Prone to spikes | Passive (No Sensors) |

Thermal and Electrical Stability Analysis

The main distinction between these adapters is that they are capable of keeping a thermal handshake with the vehicle. Verified and genuine adapters such as Tesla, Lectron, and A2Z have inbuilt sensors that interact directly with the battery management system of the car. When the pins start to overheat because of a loose connection or high ambient temperatures, these adapters instruct the vehicle to derate or reduce the current, avoiding structural damage.

Uncertified imports, on the contrary, do not have active thermal monitoring. In a prolonged charging cycle, these budget adapters often experience “thermal wandering” where the internal resistance rises with the temperature of the unit. This frequently causes the vehicle to throttle charge rates, even to 6kW, to avoid a complete thermal runaway. Certified models have high-quality silver-plated copper connectors that allow current to be maintained even in the last, most heat-intensive phases of a fast-charge cycle.

The UL 2252 mark should always be checked on the product casing before use. A non-certified adapter may save you 50 dollars now, but the cost of a certified unit of a well-known brand such as Lectron or Tesla will give you the alloys and flame-resistant materials that are precision engineered to withstand a high-power summer charging session without the need to spend thousands of dollars to repair the charging port on your car.

Home Charging Station Buying Guide: What Type is the Best Value at the Moment?

Why NACS Charging Stations are the “Investment Product” of the Future

By 2026, NACS is the universal standard of almost all new EVs. A NACS charger is no longer a personal luxury, but a strategic home upgrade. For households with multiple brands, universal charging stations (like those from BENY) offer the best ROI. These units feature integrated adapters to support both tesla charging and legacy J1772 vehicles. By making your property match the standards of the industry today, you do not require future owners to upgrade old J1772 hardware retroactively. This future-proofed installation will provide physical resale value, and your home will be more appealing to the overwhelming majority of EV drivers who now demand NACS-native infrastructure.

Highly Recommended: Universal Charging Stations

In the case of a household that has several EV brands, the universal chargers such as Tesla Universal Wall Connector or the universal series of BENY have the best ROI. These units have an inbuilt J1772 adapter that is embedded in the NACS holster.

The design is smooth: the adapter will remain connected to the plug on older cars and will be in the dock on cars with NACS. This no-regrets solution eliminates the inconvenience of loose, third-party adapters and makes sure that any visitor or subsequent purchaser can charge his vehicle instantly, no matter what type of port it has.

EV Charger Decision Matrix: Find Your Best Value

This guide will assist you in selecting a charging solution that will balance your present vehicle requirements and future property value. Select your particular situation below to get a clear cut recommendation.

| If Your Vehicle Is… | Ownership Timeline | Investment Goal | Recommended Purchase |

|---|---|---|---|

| Tesla or New 2025+ EV | 3+ Years | Maximize Property Value | Native NACS Station |

| Older J1772 EV | < 2 Years (Trading soon) | Strategic Transition | NACS Station + J1772 Adapter |

| Older J1772 EV | 5+ Years / Long-term | “No-Regrets” Flexibility | Universal Station (Integrated NACS & J1772) |

| Mixed EV Household | Any Timeline | Ultimate Convenience | Universal Station (Integrated NACS & J1772) |

The most optimal value is achieved in 2026 by focusing on long-term “future-readiness” as opposed to short-term hardware repairs. A Native NACS station offers the most convenient experience to new EV owners, and a Universal Station is the best investment to make when having a mixed-fleet household and maximizing the resale value of the home. To drivers who are already switching between car types, the NACS + Adapter solution will make sure that your property is fitted with the modern infrastructure today, so that when you upgrade to a newer car, you do not have to spend a lot of money replacing the hardware.

Choosing the appropriate standard is a clever initial move, yet the real prize is hardware that will last you at least three cars. This is where BENY comes in and makes these future-proof strategies the most reliable and industrial-grade charging experience in your home.

BENY EV Chargers: Future-Proof Solutions to all Standards

BENY New Energy leverages 30 years of manufacturing excellence to bridge the gap between legacy J1772 and modern NACS infrastructure. With extensive compatibility across North America and Europe, our hardware is built to the highest industrial standards.

Partnering for Reliability: The BENY Manufacturing Advantage

Effects of Global Standards on Manufacturers

Global standards are the strategic map of industrial development, which determines the rate of innovation and the conditions of market availability. To the manufacturers of EV charging, the standardization of the NACS (SAE J3400) is a turning point that is now reorganizing the production lines and supply chain priorities worldwide.

The adoption of the SAE J3400 standard by large OEMs such as Ford and GM has turned NACS into a proprietary design into the North American standard, which is estimated to control more than 80 percent of new infrastructure implementations. In the case of manufacturers, to remain competitive, they need to go deep into technical compliance, that is, ISO 15118 protocols, thermal monitoring logic, and IK10 durability ratings. The comprehensive documentation of these exact specifications is a high-value information hook to obtain authoritative B2B backlinks in engineering hubs and industry associations.

This change is also creating a high-margin path to liquid-cooled NACS cables and sophisticated high-voltage connectors. The supply chain is shifting to low-resistance alloy materials and fine thermal management systems to support 350kW+ ultra-fast charging. The ability to master these elements is the new technical high ground and it provides suppliers with a great chance to win the next generation of charging infrastructure in North America.

Conclusion

The EV industry shift to NACS is the shift of the industry out of the chaotic dial-up phase to the high-speed fiber optic future. While J1772 was a necessary bridge, its mechanical complexity cannot compete with the physical durability and digital integration of NACS.

The statistics cannot be denied in 2026: NACS (SAE J3400) has better ergonomics, reduced commercial installation expenses through 277 V support, and a stronger digital platform of the smart grid. To both consumers and businesses, it is a straightforward plan: to prevent hardware obsolescence, adopting the NACS standard today is the smartest move for any EV owner in the united states. The charging handle is the disposable razor of the EV world; be sure to get the one that does not break at the time you need it most.

FAQs

⚡ Can NACS chargers only charge Tesla?

No. Although it started as a proprietary design, NACS has moved to the open SAE J3400 standard. It has become the standard language of North American EVs, with large manufacturers such as Ford, GM, and Hyundai adopting it to make sure that their drivers have access to the best charging infrastructure possible.

🔌 What is the reason NACS is becoming standard?

NACS has a more refined, smaller form factor, which supports both AC and DC charging with a single set of pins. Its technical excellence, such as native 277 V operation of commercial locations and a powerful digital protocol of “Plug and Charge” made it the unavoidable victor in the efficiency and convenience pursuit of the industry.

⚡ Is NACS replacing J1772?

Yes. NACS is practically a successor of J1772 in the North American market. Although legacy J1772 infrastructure will continue to be used in the coming years, nearly all new vehicle manufacturing and public station installations are moving to NACS to establish a single, frictionless charging environment.

🔌 Does Tesla have a J1772 to NACS adapter?

Yes. Tesla provides a J1772 adapter with its cars to act as a transition to the old world. This will enable owners to use the existing network of older public Level 2 chargers as the industry fully transitions to the NACS standard.

© 2026 NACS vs J1772 Charging Standards Guide – Professional EV Charging Solutions