A Complete Guide to Commercial & Industrial Solar PV Design

Share this article in Social Media:

- Home

- A Complete Guide to Commercial & Industrial Solar PV Design

What Is A Solar PV Project & Why It Matters?

A Commercial and Industrial (C&I) solar PV project is the construction of a power plant on-site that directly transforms sunlight into electricity to power your business. The significance of it is simple: it gives you direct control over your energy future. You can create your own clean power, which is a potent instrument to control unpredictable electricity prices, achieve sustainability objectives, and provide stability in operations, transforming a fluctuating cost into a long-term, predictable asset.

Why Commercial & Industrial Solar is a Strategic Business Asset

A C&I solar system is not merely an environmental statement; it is a high-performance financial resource that provides real returns by solving major business issues. The main strategic strengths are:

- Huge Savings: Directly reduce and stabilize your electricity bills by producing your own power on-site. This secures your budget against unexpected increases in utility rates over the next several decades.

- Enhanced Brand and ESG Value: Clearly demonstrate your commitment to sustainability. A solar installation will greatly enhance the ESG (Environmental, Social, and Governance) rating of your company and will boost your brand image among customers, partners, and investors.

- More Energy Resilience: Lessen your reliance on a weak electrical grid. When paired with energy storage or microgrid-ready inverters, a solar system can provide backup power. Which is crucial in ensuring that critical processes are not disrupted and expensive downtime is avoided.

Core Components of a C&I Solar System

A commercial solar PV system is an integrated assembly of highly engineered components working in concert. Understanding the function of each core component is essential for appreciating the design process and making informed procurement decisions.

Solar Panels (PV Modules)

The most visible element of the solar system is the solar panel, or the PV module. The panels are made up of an array of solar cells, usually silicon-based, which carry out the photovoltaic effect, which is the conversion of photons in sunlight to direct current (DC) electricity. High-efficiency monocrystalline or polycrystalline panels are a common application in the C&I industry to make the most out of the available rooftop or ground space. The choice of the solar module is a very important initial step that determines the total power output and the physical area of the solar installation.

The Conversion Hub: Inverters

The solar power plant is made up of inverters. Their important role is to transform the DC electricity generated by the solar panels into alternating current (AC) electricity. Commercial buildings and the utility grid use the standard form of power, which is AC power. In commercial solar applications, various inverter types can be used, such as large central inverters to serve the whole system, or a number of string inverters to serve power on various parts of the solar array. The inverter technology selected has a direct effect on the efficiency of the system, flexibility in design, and maintenance procedures.

| Criteria | Large Central Inverters | Traditional String Inverters | String Inverters + Optimizers |

|---|---|---|---|

| Initial Cost | Lowest on a $/watt basis for large, uniform sites (>1MW). | Low to Medium. Cost-effective for a wide range of C&I projects. | Highest. Optimizers add a per-module cost to the system. |

| O&M Complexity | Low (fewer units). However, a single failure results in 100% system downtime. | Medium. A single failure only impacts one section of the total solar array. | Higher. More electronic components on the roof to monitor and service. |

| Shading Mitigation | Very Poor. The performance of a massive array section is limited by the single worst-performing panel. | Poor. The performance of an entire string is limited by its lowest-producing (e.g., shaded) panel. | Excellent. Each panel produces its maximum power independently of others. |

| Design Flexibility | Low. Requires large, identical blocks of panels in the same orientation and tilt. | Medium. Allows for multiple arrays, but each string must have a uniform orientation. | Excellent. Enables designs across multiple roof planes, orientations, and tilts, even within the same string. |

| Module-Level Monitoring | No. Only provides system-level or inverter-level data. | No. Only provides string-level or inverter-level data. | Yes. Provides granular data on the health and performance of every individual module. |

| Safety | Standard. Module-level rapid shutdown is more complex to implement. | Standard. Can be paired with certified string-level rapid shutdown devices. | Highest. Natively provides module-level rapid shutdown, the safest solution for first responders. |

The choice of inverter should be a direct response to the project’s specific needs. Use the following framework to guide your design decision:

- Choose a Large Central Inverter if: your project is a large-scale (>1 MW) ground-mount or carport with a simple, uniform design, no shading, and the primary goal is minimizing the initial cost per watt.

- Choose Traditional String Inverters if: your project is a standard C&I rooftop with a simple layout, minimal to no shading, and the goal is to find a balance between upfront cost, reliability, and ease of maintenance.

- Choose String Inverters + Optimizers if: your project site has any of the following characteristics: complex or unavoidable shading, multiple roof planes with different orientations or tilts, a need to maximize every possible kilowatt-hour of energy production, or a strict requirement for the highest level of safety via module-level rapid shutdown.

Racking & Mounting Systems

The racking and mounting system is the structural base that holds the solar panels to the roof of a building or the ground. This is a designed structure that is essential to the stability and sustainability of the whole solar energy system. In the case of rooftop installations, there are attached mounts that penetrate the roof and ballasted mounts that hold the array in place without penetrations. In the case of ground-mounted systems, one can have fixed-tilt systems or tracking systems that track the direction of the sun. The mounting system should be such that it can support the local wind, snow and seismic loads throughout the entire life of the project.

Distribution & Safety Gear

This group includes the fundamental electrical equipment that safely conducts, unites, and safeguards the passage of power within the system. It consists of wiring, fuses, and combiner boxes, which combine the output of several strings of panels. Importantly, it also incorporates circuit breakers and disconnect switches that offer overcurrent protection and a way of de-energizing the system safely to allow maintenance. These are the main parts of the system that make the PV system the central nervous system, which guarantees the reliability and safety of power flowing between the panels and the point of use.

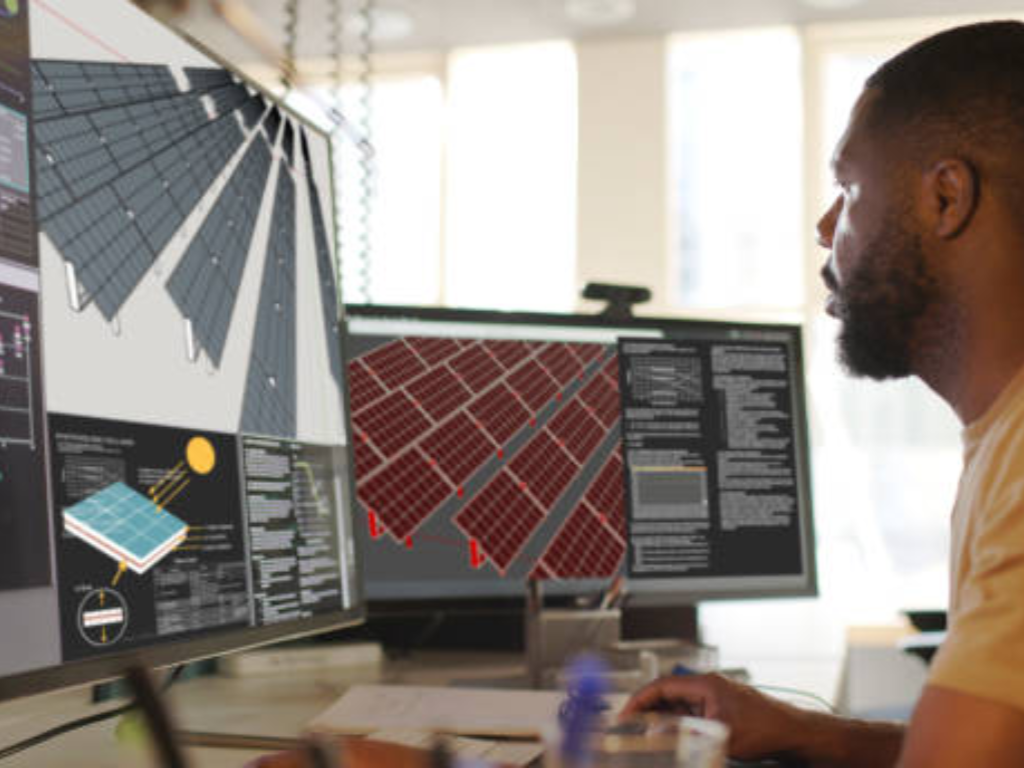

Monitoring & Control Systems

The current commercial solar systems have advanced monitoring and control systems. These systems offer real-time information on energy generation, performance of the components and the health of the system. Facility operators and system operators are able to monitor the important metrics, get automatic notifications about possible issues, and create reports to check performance and financial gains. This intelligence layer is essential to proactive maintenance, which will guarantee the system is running at its optimum efficiency and will provide the anticipated energy savings throughout its life.

The Project Lifecycle: A Phased Approach

An effective C&I solar project is a planned effort that takes an idea to an operating asset in a sequence of specific steps. This lifecycle strategy aims at reducing risk, ensuring quality assurance, and giving all stakeholders clear points of decision. To get through the intricacies of solar development and design, it is important to understand how this process works, starting with feasibility and going on to operation.

Phase 1: Feasibility and Strategic Site Assessment

This is the first step, the analytical basis of the project, which is to provide an answer to the key question: Is this a technically feasible and financially viable investment? It is a cheap, high-value step that gives the information required to make an informed go/no-go decision prior to investing a lot of capital.

Major Measures towards a Comprehensive Evaluation:

- Electricity Bill and Interval Data Analysis: The key to any proper financial model is a thorough analysis of how the facility uses electricity. This involves getting a minimum of 12-24 months of 15-minute interval data of the utility company that will indicate important trends in peak demand that cannot be determined by mere monthly bills.

- Technical Site Survey: A physical and digital survey is carried out in order to determine the practical opportunities and limitations of the site. This involves a structural evaluation of the load-bearing capacity of the roof, an analysis of the current electrical system (transformer capacity, switchgear), and in many cases a drone survey to generate a 3D representation to do accurate shading analysis.

- Preliminary Financial Modeling: A 25-year financial proforma is constructed using the data obtained. This model estimates the energy savings, operational costs, and possible revenue of the system and computes such important measures as the Internal Rate of Return (IRR), Net Present Value (NPV), and the payback period.

Phase 2: Sizing Your System for Maximum ROI

After establishing the feasibility of a project, the next step is to establish the optimal financial size of a project. The main idea here is fundamental: the aim is to maximize the return on investment (ROI), rather than the installed capacity. In areas where the net metering or energy export policy is poor, a situation of diminishing returns can be experienced, whereby the larger the system, the less the revenue. As such, the size of the system should be made in such a way that it creates the ideal balance between energy generation, the local utility rate structure, and the project-specific financial goals.

The design process should start with a clear business goal. To begin with, the main purpose of the installation should be identified:

- 100% Energy Offset. This is usually the objective in areas with good net metering policies, where the exported energy is credited at or close to the retail rate.

- 100% Self-Consumption. This is the goal in regions where the rate of export of solar is low or zero, and it is not economical to export surplus power to the grid.

- Maximum Internal Rate of Return (IRR). This is the most widely used and financially advanced optimization objective of C&I projects.

Professional designers use marginal benefit analysis to determine the sweet spot that will maximize the IRR. This is done by modeling the financial returns of the project at different capacity increments. The IRR and NPV of each possible system size can be calculated, allowing the designers to identify the point of diminishing returns, the size of the system at which additional panels will start to pull the overall rate of return of the project down. As an example, a roof of a factory can host a 1 MW system. Nevertheless, it could be analyzed that the IRR of the project is maximized at 15 percent with a 750 kW system because of low weekend energy consumption and a low export rate. The size increased to 1 MW, and the overall energy produced, might result in a decrease in the IRR to 13.5% since a significant part of the energy is sold to the grid at an extremely low price. The size that is most economical in this case is 750 kW.

Other important factors that need to be included in the design before the finalization of the capacity are:

- Energy Storage Potential: When the utility rate structure contains high demand charges or large price variations between on-peak and off-peak periods, the addition of a battery storage system to shave the peaks or arbitrage the rates can radically enhance the value of a project. This involves a combined simulation to determine the best capacity ratio of PV and storage.

- Future Load Growth: The design must consider the predictable increases in energy use, including expansion of a facility or the proposed implementation of a large fleet of electric vehicle chargers.

- Grid Capacity Constraints: The local utility can be limited by technical reasons or an elaborate approval process that limits the size of a system that can be interconnected at a particular point. It is necessary to communicate with the utility early to prevent hindrances at a later stage.

It is important to mention that the quality of all these optimization studies relies entirely on the quality of the data collected during Phase 1, that is, at least 12 months of 15-minute interval load data and the appropriate utility rate tariffs. Any advanced financial model is just a house of cards without a sound database.

Phase 3: Core Engineering and Electrical Design

It is the stage during which the project moves out of the concept and into a detailed, constructible set of construction documents. The most critical element in the timely completion of a project within budget and to the best standards of quality and safety is a professional and exhaustive design.

- Electric Design: This is the technical core of the project. Engineers carry out important calculations to determine the size of strings (how many panels per series, depending on voltage and temperature), conductor size (what kind of wire gauge to use to reduce energy loss), and overcurrent protection to make the system safe.

- Structural Engineering: A licensed structural engineer shall prepare a stamped report that confirms that the racking system and connection techniques are capable of supporting the local wind and snow loads as per building codes.

- The Permit Plan Set: The last product is a complete set of permitting and construction drawings. This should not just cover the mechanical layout of the panels and the Single-Line Diagram (SLD) of the electrical system, but also elaborate equipment specifications in a Bill of Materials (BOM).

Phase 4: Installation, Commissioning, and Grid Interconnection

The project enters the physical construction and grid integration phase with a completed design. Here, the emphasis is on quality control and the formal process of making the system online.

- Installation: The construction team constructs the system based on the specifications of the engineering plan established. The design engineer usually stays on to respond to any Requests for Information (RFIs) and to check on any field proposed changes.

- Commissioning (Cx): This is a very important quality assurance measure. A qualified technician conducts a set of elaborate tests before the system can be energized, including insulation resistance testing and IV-curve tracing on solar strings. This is done to ensure that the system was constructed properly and is operating safely as per the design requirements. Every outcome is reported in a formal commissioning report.

- Grid Interconnection: The last step is to have formal Permission to Operate (PTO) by the local utility company. This includes the filing of the final inspection documentation and waiting until the utility approves the system to officially connect and run in parallel with the grid. This administrative procedure may require a number of weeks and has to be included in the project schedule.

Beyond Panels: Selecting Critical Safety Components

While solar panels and inverters are the primary engines of energy production, the safety, longevity, and operational uptime of your commercial solar asset depend entirely on its electrical safety components. These devices—circuit breakers, disconnects, and rapid shutdown units—are not passive accessories; they are active protection systems. Understanding what they do, when you need them, and how to select them is fundamental to mitigating risk and protecting your long-term investment.

The Role of Critical Components in System Security

A commercial solar array is a high-voltage DC power plant that runs on your property. To handle this power safely and to guarantee the system has a long life, a set of important safety elements is needed. They have different and essential protective purposes.

- DC Circuit Breakers: These are intelligent safety switches. Their main task is to offer overcurrent protection. When the current in a circuit is too high because of a fault, the breaker will automatically open and the flow of electricity will be broken, avoiding the destruction of equipment or a fire. They also have a manual switch that can be used to de-energize a circuit to perform maintenance.

- DC Disconnect Switches (Isolators): A circuit breaker may also serve as a switch, but a special DC disconnect switch is provided, whose main purpose is to safely isolate a section of the solar installation as compared to the rest of the system. This is a very important maintenance safety precaution, to make sure that an inverter or other equipment is fully de-energized and cannot be accidentally switched on when a technician is working on it.

- DC Surge Protecting Devices (SPDs): These are the elements that protect the system against voltage spikes. Such incidents as lightning strikes nearby or grid surges may impose harmful high-voltage transients on the system wiring. An SPD identifies these spikes and redirects the unwanted energy to the ground safely, ensuring that costly equipment such as inverters and monitoring systems is not destroyed.

The Need for Integration in Commercial Systems: The Combiner Box

These components may be installed separately in a small residential system. Nevertheless, dozens of parallel strings of solar panels are common in commercial and industrial (C&I) projects. It would be complicated, expensive and would introduce many possible failure points to manage the wiring and offer individual protection to each string.

This is why C&I systems nearly universally use a Combiner Box. A combiner box, as the name implies, is an electrical housing that is intended to safely combine the output of several solar strings into one larger main cable.

More importantly, the combiner box is also the central housing where the most important safety components are combined. A standard commercial combiner box will include:

- Each string has overcurrent protection (either fuses or DC circuit breakers).

- A primary DC disconnect switch to isolate the whole array.

- DC Surge Protecting device (SPD) to guard all the strings connected.

A combiner box simplifies the wiring process by incorporating these devices into a single, strong, factory-assembled unit, increases safety, and concentrates the protective functions of the system. In choosing a solution, it would be the industry practice to source a pre-wired and certified combiner box from a manufacturer such as BENY. This method will ensure that all internal parts are rated and installed to the utmost standards, which will save a lot of labor on-site and also eradicate the frequent mistakes that can occur during wiring, which may jeopardize the safety and performance of the system.

Ensuring Rooftop Safety with Rapid Shutdown Devices (RSD)

Rapid Shutdown is a compulsory safety need in most areas, such as those that adhere to the U.S. National Electrical Code (NEC). It is designed to give a means of de-energizing the solar panels on the roof within a short period of time to shield first responders against the risk of shock during an emergency.

How you achieve this depends entirely on your choice of inverter technology.

- Scenario 1: Systems that have Built-in RSD (Microinverters or Optimizers). If your system has Module-Level Power Electronics (MLPE), e.g., microinverters or power optimizers, the necessary rapid shutdown functionality is often integrated directly into each unit. Here, you are not required to buy individual RSD components; the system is by design compliant.

- Scenario 2: Systems that need Add-On RSD (String Inverters). In the case of traditional string inverters, which are a very popular option on C&I projects, the inverter itself cannot de-energize the panels. Thus, you are required to install a special rapid shutdown device at every module (or two modules)

How to Select: The selection of the add-on RSD unit is important in this case. The most important selection criteria are:

- Certification: The equipment should be UL Listed and, to be interoperable, SunSpec Certified. This makes sure that it is safe and able to communicate properly with the inverter and other parts of the system.

- Reliability & Compatibility: The RSD should be demonstrated to be reliable over decades under severe rooftop conditions. That is why special RSDs of professional manufacturers such as BENY are a reliable option. Their certified and universally-compatible units are designed specifically to offer a strong and conforming rapid shutdown solution to any string inverter system, offering designers a reliable route to safety codes.

Navigating Global Standards and Component Quality

Objective verification is essential for a long-term commercial solar asset. True quality is validated through independent testing and certifications from internationally recognized authorities. Understanding these standards allows you to accurately assess the safety and reliability of the components selected for your project.

This section outlines two frameworks used by industry experts to evaluate component quality, covering mandatory requirements and indicators of long-term performance.

Essential Safety Certifications

Safety certifications are the baseline requirement for any component used in a solar project. They confirm that a product has passed rigorous testing for electrical safety and its ability to withstand specific environmental conditions. These certifications are non-negotiable for legal installation and ensuring project safety.

Key standards to verify for major components include:

- Solar Panels: Look for IEC 61730 (international) or UL 61730 (North America). These standards test for safety and performance under stresses like hail, high temperatures, humidity, and mechanical loads.

- Inverters: UL 1741 is the critical standard in the U.S. It validates essential grid-interaction safety functions, such as anti-islanding and proper voltage/frequency response.

- Safety Components (Switches, Breakers): These require specific certifications for their function. For instance, DC disconnect switches designed for solar applications should be certified to standards like UL 508i, proving their capability to handle high-voltage DC loads safely.

A manufacturer’s commitment to securing a broad range of global certifications is a strong indicator of robust quality control. For example, when a company like BENY holds certifications from UL, TÜV, CE, and SAA, it demonstrates that its products meet the highest safety benchmarks in multiple demanding international markets.

Independent Reliability Testing

Beyond mandatory safety standards, independent reliability tests predict a component’s long-term durability and performance. These tests subject products to conditions far more severe than standard certification protocols to simulate decades of real-world operation.

For solar panels, the most respected benchmark is the PV Evolution Labs (PVEL) PV Module Reliability Scorecard.

- What it means: PVEL conducts accelerated stress tests for factors like thermal cycling, damp heat, and potential-induced degradation (PID).

- Expert Advice: Prioritize panel models that have been designated a “Top Performer” by PVEL for several consecutive years. This indicates manufacturing consistency and a higher probability of long-term performance.

Top-tier electrical component manufacturers apply similar principles through extensive in-house testing, such as salt spray and IP (Ingress Protection) assessments, to validate product endurance in diverse and challenging environments.

Optimizing Long-Term Performance with O&M

The commissioning of a solar PV system marks the beginning, not the end, of its operational life. To ensure the system consistently delivers its projected energy production and financial returns, a proactive Operations & Maintenance (O&M) strategy is essential. A robust O&M plan protects the asset’s value and maximizes its performance over time.

O&M activities are typically divided into two categories. Preventative maintenance includes scheduled tasks such as cleaning solar panels to remove dirt and debris that can reduce energy output, inspecting electrical connections for tightness and corrosion, and verifying that inverters and monitoring systems are functioning correctly. Corrective maintenance involves responding to system faults or failures. With a comprehensive monitoring system in place, many potential problems can be identified and addressed before they lead to significant downtime. Neglecting O&M can lead to a gradual degradation in performance, eroding the cost savings and ROI that justified the initial investment.

Need Help Specifying Safety Components?

Conclusion: Build Your Solar Future with Confidence

A successful Commercial & Industrial solar project is the direct result of meticulous planning, expert engineering, and an uncompromising commitment to quality. As a long-term asset designed to perform for over 25 years, its success is ultimately determined by the reliability of every component—especially the critical safety and distribution gear that protects your entire investment.

To build your solar future with confidence, prioritize partners and component manufacturers with proven experience and a portfolio of globally certified products. By ensuring your system is built with high-quality, durable components from the start, you secure decades of predictable, clean, and profitable energy.

© 2025 C&I Solar Project Guide – Professional Solar Solutions